The surprise is that there's some seriously solid evidence in the British Museum "World of Stonehenge" Exhibition that people in early Neolithic Britain were brewing beer. And it looks like it was on a large scale. The World of Stonehenge has been described as a 'once in a lifetime' experience and has taken ten years to organise. It opened on February 17th and will close on the 17th July 2022 when the exhibits will be returned to their original locations in museums all over Europe. There are fabulous gold artefacts, beautiful flints and even part of a timber circle. But the most interesting part of the exhibition, for me, is the acknowledgement that brewing beer was an important part of the Neolithic lifestyle six thousand years ago. People knew how to transform cereal grain into alcohol. It seems that this once controversial idea is now acceptable in academic archaeological circles and it's time to talk about it. Thanks to the British Museum.

What is this surprising evidence? I contacted the organisers in early February when I first heard about this forthcoming exhibition. I asked them whether malt and ale were included. The response was that, yes, they had written a few sentences on 'beer' on page 50 of the accompanying book. I wondered what that evidence could be. Graham and I have been doing research into ancient and traditional beer brewing techniques and the potential archaeological evidence for malt and ale for over twenty years. We have been arguing that there's more to grain processing than flour and bread, porridge or gruel. Grain can be malted.

Could the evidence be the analysis of burned cereal residues on large Grooved Ware pots? Was it the discovery of carbonised malted grains, which are associated with beer brewing activity in the past? I had to buy the book to find out. It's neither of these established archaeological aspects of evidence.

"The tridents may have been used for fishing or eel trapping, or in agricultural activities as hay forks, and even as mashing forks in the process of beer brewing. It is likely that farmers were using some of their cereal harvests to make alcohol for social and religious gatherings rather than consuming only sober porridge and savoury foods."

(Garrow, D. & Wilkin, N. The World of Stonehenge, published by The British Museum, 2022 page 50)

This is how I discovered that the archaeological evidence for beer brewing in early Neolithic Britain on display is in the shape of two very large and very solid oak tridents. They were discovered in 2008 during excavations at Stainton West, Cumbria, by Oxford Archaeology North. Details and excellent photographs of the excavations and the discoveries can be found here on their web page. As the photographs show, it was a complex and very wet and muddy dig. Wellington boots were obligatory. Congratulations to the team on their work.

Until now, apart from a few comments on social media and a private conversation, these tridents have been described as mysterious and enigmatic, a rare and unusual find. Nobody knew what they were used for. Nevertheless, they are deemed important and significant objects. Similar wooden tridents were recovered during the 19th century at Ehenside Tarn, near Ravenglass, on the Cumbrian coast of England in 1874, and another was found in a bog during excavations at Armagh in Northern Ireland (1857). These other mysterious wooden tridents are held in the British Museum stores and are, apparently, in poor condition.

The Stainton West tridents are well preserved, having been in waterlogged conditions for 6000 years. They have been beautifully restored by experts.

| ||||

(© Tullie House Museum and Art Gallery Trust)

|

There was talk on social media. Archaeologists argued, as they often do, about what they might have been. It's difficult to find these discussions now. Some of the places where it was discussed (eg Past Horizons) no longer exist. If you can find any from this time then do let us know! Suggestions from archaeologists and historians included eel spears, hay forks or supports for fishing nets.

I suggested that they may have been mash forks, similar to those used by Arnold of Soissons, the patron saint of brewing. A mash fork is one of the traditional symbols of the brewer. These wooden "tridents" would have been ideal as mash forks. That's the

tool used for stirring the crushed malt into hot water in the mash tun, a

crucial part of the beer brewing process, the saccharification, when the malt sugars are made. Sometimes referred to as a mash rake, it is a piece of equipment that is crucial to the 'mashing in' stage of the brewing process. Don't confuse it with a malt rake, which is a tool the maltster uses to rake and turn the grain on the germination or malting floor.

This is a well known image that many brewers and brewing historians are familiar with. It's a stained glass window in the Sainte-Glossinde Chapel in Metz, Moselle, France, that depicts St Arnold (1040-1087) with Bishop's mitre and his mash fork.

The idea of tridents as mash forks was an idea that was not taken very seriously at the time. But, interestingly, I was not the only person to suggest mash forks or an early form of mashing rake. Here's a comment on the article on The History Blog entitled "Mysterious wood tridents on display" from 2013:

Sophie must be a brewer. She knows what a mash fork is. In her comment she gives two links, one to St Arnold of Soissons and another that shows the brewer's traditional tools of the trade. These are a malt shovel for turning the germinating grain on the malting floor, a mash fork (or rake) for the mash tun and a long handled brewer's ladle. The mash rake in this image has struts to strengthen it.

|

| See http://www.schlenkerla.de/biergeschichte/brauerstern/bilder/Wappen.jpg |

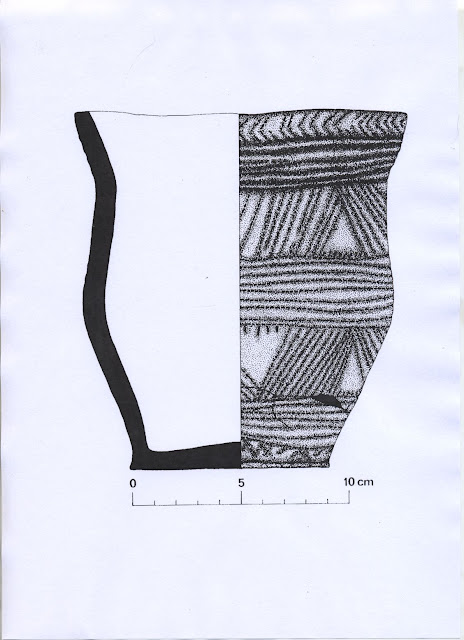

The tridents had been expertly crafted, using stone tools, from single radially split planks, cut from mature oak trees. A long shaft was tapered at one end, at the other end widening into two projecting wings, or steps, and then three, long, tapering tines. Only one of Trident 1's tines survived, while one tine from Trident 2 had broken off, but remained closely associated with the object. Both tridents were approximately 2m long and would have been heavy, unwieldy objects, made from logs that were much larger than strictly necessary; these appear to have had near-identical diameters of 0.4m. These logs had been split in half, then into quarters, and finally eighths, forming a wedge sectioned plank."

This is the first time that I can find a published reference to "mash forks (used for brewing beer)". Until 2019 this idea was, as far as I know, only discussed on social media. In 2018 I had a private conversation with one of the Oxford Archaeology North team on Twitter, giving them details of mash forks, their design and function in the brewing process. The next thing I know it's an accepted interpretation in the World of Stonehenge, both in the British Museum and in the book. I'm still trying to figure out how a private twitter conversation in 2018 becomes a possible interpretation in the British Museum Exhibition. There is no acknowledgement or detail about where this new interpretation came from.

Nevertheless, as I wrote earlier, many thanks are due to archaeologists of Oxford Archaeology, to the British Museum curators of the exhibition and to the authors of the World of Stonehenge book. They have corroborated our idea that, in the Neolithic, cereals were cultivated to make malt, malt sugars and ale rather than flour, bread, porridge, gruel or even pastry for mince pies, as has been suggested recently by archaeologists at English Heritage. It seems that they have completely missed the fact that grain can be malted and mashed to make malt sugars and wort for fermentation, even though we wrote a blog about it for them.

A mash fork needs a mash tun.

When Graham makes beer he "mashes in" using a small five gallon mash tun. A long handled plastic spoon is enough to agitate the mash as crushed malt is added to the hot water. These 6000 year old neolithic tridents are around six feet long. Obviously, they would have been used in a very large mash tun. Given that the archaeologists excavated five burnt mounds, with evidence of associated troughs, at Stainton West there is no need to look further for a potential mash tun. I have asked the archaeologists for more details on the troughs and was told that they measured roughly 2x1.5m. I was not given a measurement of the depth. They are probably a similar depth to most burnt mound troughs and may have held a volume of 200 to 400 litres.

The first archaeologists to suggest that the troughs at burnt mound sites were used as mash tuns were Declan Moore and Billy Quinn from The Moore Group, based in County Galway, Ireland, where these sites are known as fulacht fiadh. Billy and Declan did all the research and followed it through with practical experiments and demonstrations. In 2008 they did an impressive presentation at the World Archaeology Conference (6) in Dublin. I was happy to help out. They had made a large wooden trough, sealed it with bitumen, and heated stones in a fire, using a garden fork to transfer them into the trough. Crushed malted barley was added to the hot water, a traditional technique to mash in. It was a successful mash and a spectacular demonstration.

| ||||

| The Moore Group added hot rocks to a trough using a garden fork at WAC 6 Dublin 2007. | |

|

| Our Bressay strike in 2010: hot water, crushed malt, stone trough and a garden fork. We used 200 litres of water and 50kg of crushed malt. |

|

| Map of Stainton West excavations from Bridging Time's Deep River, produced by Oxford Archaeology North 2019, p 38 |