We visited the island of Wyre in Orkney, and inspected "Cubbie Roo's" castle. This was built by Kolbein Hrugr, hrugr means "heap", he was a big man. It is mid 13th Century and one of the older mortar and stone built castles extant in Scotland. It is a fascinating site on one of the now remoter islands of Orkney. We were surprised, amazed and overwhelmed to find a stone built "mash oven" in an outbuilding round the back. Our excitement was because this could be the oldest mash oven in Europe. This building has a stone bench, perfect as an ale store, and drains. It would be very suitable for making ale, but so far archaeologists have interpreted this as just an ordinary oven.

|

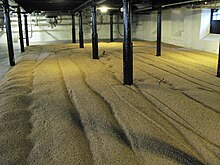

| Cubbie Roo's mash oven, Wyre, Orkney. |

|

| the medieval brewer, stirring the mash |

We are lucky on Orkney to have well preserved Viking sites. A friend and neighbour suggested that we might like to look at the drains at the site on the Brough of Birsay.

Birsay is the late 10th Century base of Sigurd the Stout and his son Thorfinn. In the Orkneyinga Saga they are renowned for their hospitality. We can imagine the great feasts they had there. This might even be the site of Sigurd's Yule Feast, where Kari slew Gunnar Lambi's son in front of King Sigtrygg of Dublin ( pp xxvii-xxviii, Orkneyinga Saga, edited by Joseph Anderson.)

Drains are significant for brewing installations. The mashing process makes sugars from the malt and these are very sticky and messy. Any spillage or accidents have to be washed away, and the brewing equipment has to be kept clean. A brewery cannot function without effective drains.

|

| one of the massive stone lined drains at Birsay |

There is a massive drain running down the middle of what I think is the head of the Viking causeway, most of which has been eroded by the sea. To the right of this causeway, looking back to the mainland, is the so called "Viking Sauna" (see photo below) with stone slabs on edge, supposedly to support wooden benching. I heard an expert on TV saying that "they poured hot water down the drain under these benches, to keep their bums warm". I think it's far more likely to be the brew house and ale store.

|

| not the sauna - this is the brew house and ale store |

|

| the mash house, with large stone shelf & several drains |

I was puzzled. These installations are little different to the Orkney Brewery, which is just down the road at Quoyloo. Rob Hill's Swannay Brewery, also on Orkney, uses the same installations - a mash tun and fermenting vessels. How on earth could anyone think that these buildings were a Bathhouse and a Sauna? Maybe they knew absolutely nothing about how beer is made.

When I get puzzled by archaeology, I like to read the original excavation reports. This tells me what came out of the ground and there are usually nuggets of really useful information that are lost or not mentioned in summaries.

The earliest reference to 'Viking Bathhouses or Saunas' that I could find came from Dr Alexander Curle's excavations at Jarlshoff, Shetland, published in 1935, in the Proceedings of the Society of Antiquaries of Scotland (PSAS 69). He wrote that "...the presence of such a drain, and the condition of the ash deposited within it, suggest the possibility of the remains of a bath-house existing nearby." (page 284).

Curle explains that this is the first Viking settlement excavation in Britain, and that his interpretations are based upon the work of Thorsteinn Erlingsson, who wrote about Icelandic settlements. In his book Ruins of the Saga Time, published in 1895. Erlingsson describes the components of the traditional farmstead house, including the bath-stofa or bathroom. He describes it as being part of the main structure and it is not a separate building.

|

| Jarlshof, Shetland - is this the bath house, hof, a religious building or a brewhouse? |

The structure in question at Jarlshof (see photo above) was beneath a mausoleum and it was not excavated until the 1950s by JRC Hamilton. Alexander Curle did not actually excavate it. In the foreground is a large longhearth and a substantial drain. To the rear of the building there is what looks to me like the bowl or footings of a grain drier.

So how on earth could Dr. Curle know that it was a bath-house, other than making the assumption that it was, because of the drains and and a means of heating water?

This remained a mystery to me until I stumbled across Dr. Alexander Curle's excavation report for another Viking age site, at Freswick, Caithness, Scotland, published in the Proceedings of the Society of Antiquaries in 1939, see PSAS 73 . In this, he describes a feature that, at first sight looks very much like a small Roman style bath-tub, with a large hearth and drains.

I was devastated, despite the complete absence of any mention of bath-houses in the Sagas, here was an archetypal bath-house. The Sagas describe the practice of bathing in streams, lakes and rivers. There were even open-air hot baths in Iceland, thanks to the natural hot springs there. Otherwise the Vikings habitually bathed in tubs of hot water in the andyri or porch. Even the King of Norway took his bath in a tub.

|

| reconstruction of Snorri Sturlussun's 'bath house' makes use of a hot spring, it is in the open air and is nothing like the buildings at the Brough of Birsay & Jarlshof. |

Then one day I re-read "The Vikings in Scotland" by James Graham-Campbell and Colleen E Batey. On page 198, the Viking settlement at Freswick is discussed:

"... as part of the re-examination of this building through the surviving records, several problems became clear, the most significant being the complete stratigraphical separation between the secondary structure and the underlying drain. These could never have been associated and thus the secondary building is unlikely to have been a bath-house."

It was now obvious to me. Dr Alexander Curle was already aware of Freswick when he excavated Jarlshof, and this had influenced his interpretation. It has also influenced the interpretations of Viking sites for many other excavators and archaeologists since then. Whenever they find drains and a means of heating water, they interpret it as a "bath-house", even though the original archetype has been found to be wrong.

Interestingly the Brough of Birsay was excavated under the direction of Dr Curle's daughter-in-law, Cecil Curle, so she would have followed the family tradition and their interpretations.

In short, most archaeologists do not know how to make beer from the grain. They certainly drink it, and they may even have made beer from kits, but they do not understand the processes, and so they do not recognise the installations in any era up until the late Mediaeval when monasteries brewed.

What a sad loss.

----------------------------------------------------------------------------------

further reading

We presented a poster at the 7th Experimental Archaeology Conference, Cardiff University. It can be downloaded here:

Where were the Viking Brew Houses?

more reading (added June 25th 2014)

We wrote a paper for the EXARC Journal, it has been peer reviewed and it is currently on the member's only section of the Journal. It will be released for everyone to access, download and read in the near future, probably later this year.

In the meantime, here is a shorter version of that paper, published in the Orkney Archaeological Society Newsletter. We called it 'Where did the Vikings make their ale?'.

Update

Lars Marius Garshol has been studying Norwegian Farmhouse brewing for a long time and is an expert in this field. The methods and equipment that he describes seem to us to have changed very little, if at all, from those of the 10C.

For anyone who wishes to understand or recreate Viking style brewing his work is an invaluable resource. Here is his Blog.

Lars' Blog